Master the Art of Reloading Ammo: A Comprehensive Step-by-Step Guide

Reloading ammunition is a rewarding and cost-effective way for gun enthusiasts to enhance their shooting experience. By handcrafting your own bullets, you can achieve better accuracy, tailor loads to specific firearms, and save money in the long run. In this comprehensive guide, we will walk you through the essential steps to reloading ammo, ensuring your safety and success in this intricate process.

Understanding Reloading Components:

Before diving into the reloading process, it’s crucial to understand the key components involved. These include brass casings, primers, powders, bullets, and the necessary equipment and tools. Each element plays a vital role in reloading ammunition and contributes to overall performance.

Why Reload Ammunition?

Shooters can get many benefits by reloading their own ammunition. One can improve the reliability, accuracy, and performance of their ammo by reloading their own cartridges. In addition, if you reload your own ammunition, you can tailor the loads to your personal needs, which should increase their accuracy and dependability under fire. Moreover, reloading might be a more economical option than buying factory-made ammo, especially for serious shooters who go through a lot of bullets.

The Reloading Process: Step-by-Step Guide

If you’re interested in improving your ammunition’s accuracy, performance, and cost-effectiveness by making it yourself, you’ve come to the right place. Learn the ins and outs of reloading ammunition with us, from cleaning cases to seating bullets.

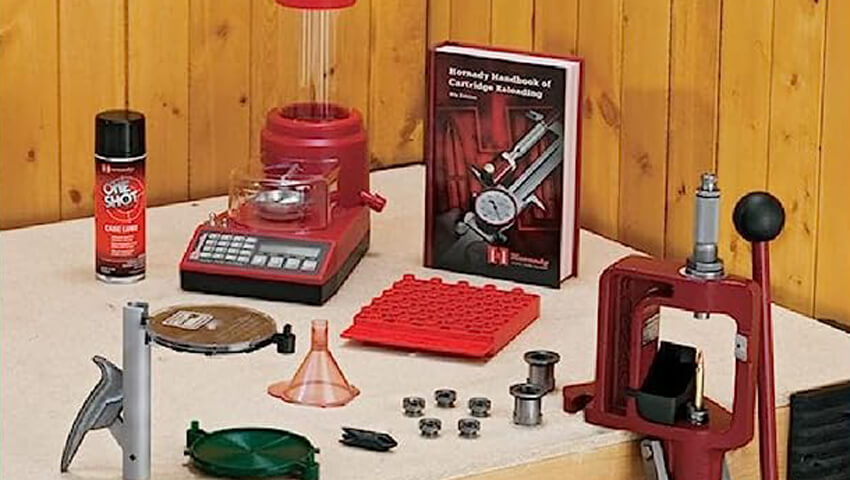

Step 1: Gather Equipment and Components

Before diving into the reloading process, it is essential to have the necessary equipment and components. Here’s a list of items you will need:

- Reloading Press: Pick a reliable press that falls within your price range and feature requirements. For those just getting started with reloading, a single-stage press is a way to go, while progressive presses allow for faster output and are best for professionals.

- Dies: Bullets can be resized, deprimed, and seated with these. Verify that you’re in possession of the proper dies for your firearm’s caliber.

- Brass Cases: Collect and inspect fired cases from your previous shooting sessions. Make sure they are clean, undamaged, and suitable for reloading.

- Primers: Small metal cups that ignite the powder charge when struck by the firing pin.

- Powders: Select appropriate powders based on the caliber and desired performance of your ammunition. Refer to reputable reloading manuals for recommended powders and charge weights.

- Bullets: Pick bullets that are the right weight, caliber, and shape for your gun. Full metal jackets (FMJ), hollow points (HP), and match-grade bullets are just some of the varieties available on the market.

- Calipers: Precise measurements are crucial in reloading. A quality caliper will help you accurately measure overall cartridge length and other critical dimensions.

- Case Prep Tools: These include a case trimmer, deburring tool, primer pocket cleaner, and chamfering tool. They are used to ensure uniformity and consistency in case preparation.

Step 2: Inspect and Prepare Brass Cases

Examine each brass container closely for signs of wear and tear including cracks, splits, or overstretching. Throw out anything that doesn’t pass muster. Next, you should give the casings a good scrub to get rid of any dust, grime, or carbon buildup. A tumbler or ultrasonic cleaner can accomplish this task. After they’ve been cleaned, it’s important to double-check if they’re ready for resizing.

Step 3: Resize and Deprime the Cases

Using a resizing die on your press, resize the brass cases to their original dimensions. This process removes any bulges and ensures proper chamber fit. Simultaneously, the resizing die will deprime the spent primer from the case. Inspect the resized cases to confirm they meet the specified dimensions.

Step 4: Prime the Cases

Reloading presses typically have a priming arm or tool where you may insert new primers. To prime a case, you must line up the priming arm with the primer pocket on a case that has been resized and deprimed. It’s important to avoid high or low seating when loading the primer, as this can impair the round’s dependability.

Step 5: Measure and Charge the Powder

Accurate measurement of powder charges is critical for consistent performance and safety. Use a quality powder scale or electronic dispenser to measure the desired powder weight. Follow the load data provided by the powder manufacturer or consult reputable reloading manuals for recommended charge weights. Carefully pour the measured powder charge into each primed case.

Step 6: Seat the Bullet

Select the appropriate seating die for your specific bullet type and caliber. Place the bullet on top of the charged case and raise the ram of the press, allowing the seating die to gently press the bullet into the case mouth. It is crucial to achieve the desired overall cartridge length for optimal accuracy and chamber fit.

Step 7: Crimp (If Necessary) and Inspect

If your reloading process requires crimping, utilize a crimp die to secure the bullet in place by creating a slight inward taper at the case’s mouth. Finally, inspect each completed round for any abnormalities, such as high or low primers, bullet setbacks, or inconsistent overall length.

Safety Considerations

Reloading ammunition involves working with potentially dangerous components. Safety should always be the utmost priority. Here are some essential safety guidelines to follow:

- Familiarize yourself with reloading manuals and recommended load data from reputable sources.

- Wear safety glasses to protect your eyes from potential hazards.

- Work in a clean and organized reloading area, free from distractions.

- Avoid distractions and never rush the reloading process.

- Store powders, primers, and loaded ammunition in separate, secure locations.

- Use the appropriate personal protective equipment, including gloves, when handling components.

Advanced Reloading Techniques

For those looking to further refine their reloading process, there are advanced techniques worth exploring. Case annealing, neck resizing, and sorting brass and bullets can help improve consistency and precision.

Troubleshooting and Tips

Inevitably, reloading can come with its challenges. Learn how to troubleshoot common issues such as case head separation, primer seating problems, and inconsistent powder charges. Proper storage and understanding the shelf life of reloaded ammunition are also important considerations.

Conclusion

Ammunition reloading is a fascinating and skilled activity that allows shooters to fine-tune their loads and achieve astonishing precision. Following these detailed instructions for reloading ammunition will allow you to produce custom cartridges with enhanced accuracy, efficiency, and economy. By fully immersing oneself in reloading with a focus on safety, learning, and precision, one can realize the process’s full potential.